ABOUT US

ABOUT US

Guangli Ruihong Electronic Technology Co., Ltd., with a registered capital of 500 million yuan, is a wholly-owned subsidiary of A-share listed company GL Tech Co., Ltd.. (GL Tech Co., Ltd., 300480), and specializes in the research, development, production, and sales of semiconductor dicing equipment.

GL Tech started with energy security production IoT monitoring equipment business and established a leading position in the industry with its core technology strength. From 2016 to 2021, it acquired the inventor of semiconductor scribing machine, the UK's Loadpoint, and the core component air spindle company LPB (Loadpoint Bearings), as well as the world's third-largest scribing machine company, Israel's ADT, entering into the field of semiconductor back-end packaging equipment scribing machines.

In 2021, the company achieved a rapid transformation from scratch and from 1 to N, forming a strategic layout in which the IoT business and semiconductor equipment business are equally important.

Loadpoint in the UK is the inventor of the semiconductor dicing machine, accumulating deep experience in advanced precision cutting technology in the semiconductor packaging field, and has a leading advantage in processing ultra-thin and ultra-thick semiconductor devices. Loadpoint Bearings' air-bearing spindles have always been in a leading position in the industry, and both Disco and Tokyo Precision Corporation in Japan were LPB's customers more than twenty years ago.

LPB's air-bearing spindle positioning accuracy has reached the nanometer level (usually below 10 nanometers), with outstanding advantages of ultra-high motion accuracy, ultra-high speed, and ultra-high rigidity. After the acquisition of LP and LPB, the company completed a comprehensive layout from equipment to core components, laying a solid technical foundation for promoting the localization of semiconductor dicing equipment.

ADT has decades of experience in the field of semiconductor back-end packaging equipment, and is a leader in the industry in terms of precision in semiconductor cutting and scribing. Its independently developed scribing machines have a precision control system that can achieve control accuracy as low as 0.1 microns for stepper motors. At the same time, ADT's production blades are among the best in the industry, with high customer recognition.

ADT's customers cover major markets around the world, including mainland China, Taiwan, the United States, the European Union, Malaysia, the Philippines, and Israel.

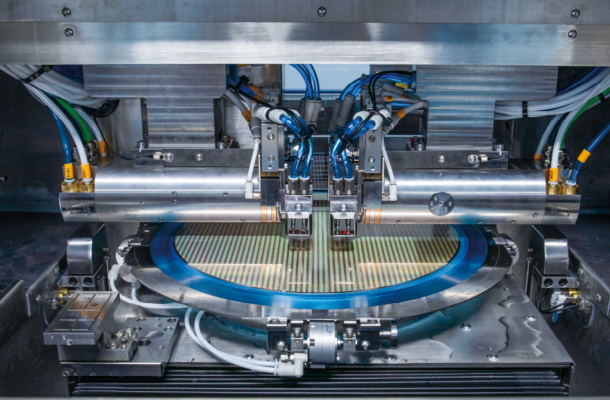

After acquiring the core technology of scribing machines through overseas mergers and acquisitions, ADT directly competes with the world's leading manufacturers of advanced 300mm wafer cutting and scribing equipment series in developing localized products.

Currently, the ADT 8230 fully automatic dual-axis 12-inch cutting machine has been widely used in well-known packaging and testing plants such as JECT, Huatian Technology, Carsem, TRS, GEM, and ATX. Its equipment accuracy, cutting yield, and cutting efficiency have been recognized by users and have resulted in repeated purchases.